~

Showing posts with label bio-diesel. Show all posts

Showing posts with label bio-diesel. Show all posts

Apr 25, 2013

Apr 22, 2013

Production, Transportation, Refining and Distribution of Palm Oil

What is actually involved in bring it to supermarkets and homes?

It can be purchased in bottles and is popular in countries that have

embraced it as a cooking oil. Some of us might not be aware that it can

also be present in many of the products that we enjoy eating. Even many

of the popular scented soap brands use Palm Oil as a major ingredient in

the manufacturing process. Palm is plentiful and a major source of

vegetable and cooking oil. If you happen to live in countries like

Malaysia and Indonesia, you cannot help but notice that certain parts of

the countryside are populated with millions of palm trees. Palm Oil has

become a major commodity on the world market and it is a growing

industry and can even be used to produce biofuel.

First of all the

Palm Trees have to be picked. It is actually the seeds that contain the

oil. These seeds are then crushed in a Mill and separated by process

systems to produce something called CPO (crude palm oil).

Once the

mill is satisfied with the quality of the oil it can be transported to

refineries. If it is being transported by land it will most likely be

kept in large containers on trucks. These trucks will deliver the

product to refineries who will process it even further into purer oil.

When palm oil is being delivered to refineries it is either sampled

manually or goes through electronic "palm oil quality monitors"

CPO

Refineries are always watching the price of the commodity which is also

traded on the stock market so timing can be important.

Finally,

these refined products are sold to agents and distributors in smaller

quantities who then use the palm oil as a base product or a component of

goods that will be found on supermarket shelves and used in homes.

Palm

competes with other types of oil such as Canola and Sunflower Oil. The

distribution of palm oil and palm oil related products will depend

mostly on the preferences of end manufacturers of products which also

can be influenced by consumer preferences. Palm for cooking is highly

respected in countries like Thailand, Malaysia and Indonesia where it is

commonly found in restaurant food. There are many benefits to using

Palm Oil in these locations but one of the major benefits is that it

will be competitively priced compared to other types of vegetable oil

which might be costlier to import.

Article Source: http://EzineArticles.com/6147210

Labels:

article,

bio-diesel,

by-product,

commodity,

edible oil,

investment,

palm oil,

palm product

Apr 21, 2013

Rapid Thermal Processing to Convert Oil Palm Biomass Into a Premium Renewable Energy Source

-->

Rapid Thermal Processing or "RTP™" is a process which adds value to biomass. In this particular case, it can be used to convert oil palm biomass into bio-oil, which can then be served to other purposes such as a renewable source of energy. Large-scale experiments have shown that the quality and yield of the resulting bio-oil is so viable, it can be considered as a premium renewable energy. Among the intended uses being renewable transport fuels.

This method of producing a renewable source of energy is based on the introduction of heat to efficiently convert oil palm biomass to produce high value products. The result is a premium renewable energy source which can be used for various purposes including power generators, green diesel and can even replace jet fuel.

The conversion of oil-palm biomass through RTP™ technology in producing a renewable energy source of fuel such as bio-oil is currently under research and development. Such pyrolysis technology exists, and has operated on a long-term commercial basis which converts the solid biomass to liquid in less than two seconds. The result is simply renewable energy from oil palm biomass.

Basically, it is a fast thermal process where the biomass is introduced into a vessel and rapidly heated to 500 deg C by a tornado of hot sand and then rapidly cooled within seconds. It generates a relatively high yield (up to 75% per weight of biomass) of pourable, liquid "bio-oil" from residual forestry or agricultural product, in this case oil palm biomass.

Pyrolysis technology exploits the thermo-chemical process of decomposing organic material at elevated temperatures in the absence of oxygen. It typically occurs under pressure and operates at high temperatures (above 430 deg C).

This process is the basis of several methods that are being developed for producing premium renewable energy from oil palm biomass.

The process is self-sustaining as it is economical, where the byproducts produced from this process are used to generate much of the heat and power required to operate the unit. It produces very little byproducts: notably char which is consumed internally to generate the required heat for the rapid thermal process; and gas, which can be used for drying the incoming biomass or for heating integration into the overall facility.

From here it is clear that rapid thermal processing in converting oil palm biomass into a premium renewable energy source provides an answer to the energy debate. The resulting clean renewable energy can be used to replace fossil fuels without the expense of changing the infrastructure of fuel engine technology, like the issue with bio-diesel.

Faiz Suberi is currently a consultant for Premium Renewable Energy (Malaysia) Sdn. Bhd. Also known as PRE Malaysia, they focus on the production of bio-oil from oil palm biomass as a source of green renewable energy.

Article Source: http://EzineArticles.com/5118670

Labels:

article,

bio-diesel,

by-product,

chemistry,

eco-system,

RSPO,

RTP

Apr 7, 2013

Mar 16, 2013

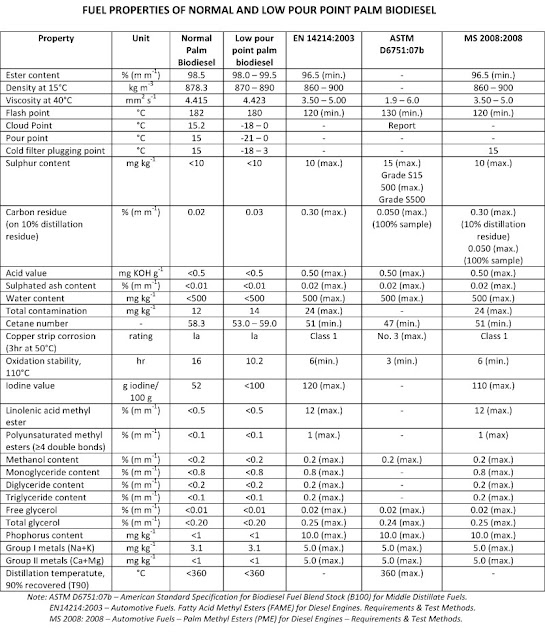

Technical Specification of BioDiesel

1. Can palm biodiesel be used directly in diesel engines?

Yes. Neat palm biodiesel (straight non-mixed biodiesel) can be

used as fuel in diesel engines without any engine modifications. It can

also be blended in any proportion with petroleum diesel.

2. What is the quality of the palm biodiesel produced using our homegrown technology (MPOB technology)?

The quality of the palm biodiesel produced using MPOB biodiesel

production technology meets the stringent specifications of

international biodiesel specifications of ASTM D6751 and EN 14214.

3. What will happen to our car engines if we revert to petroleum diesel after using palm biodiesel?

The car engine should encounter no problem as studies have shown that

palm biodiesel and petroleum diesel can be blended in any proportion.

Field Trials Using Mercedes Benz (OM352) Diesel Engines

Mounted on Passenger Buses

Mounted on Passenger Buses

4. What is Mercedes-Benz AG view about palm biodiesel?

One of the most exhaustive field trials on the use of palm biodiesel

as diesel fuel was conducted by Mercedes-Benz in collaboration with MPOB

(then PORIM) and Cycle & Carriage. A fleet of 30 Mercedes-Benz

buses with OF 1313 chasis and OM 352 engines were used for the trial.

The buses covered mileages of up to 300,000 to 351,000 km each. The

trial was conducted from June 1990 to July 1995. Followings were

Mercedes-Benz’s conclusions:

‘The test showed that OF 1313 buses with OM 352 engines which have

been actually designed for operation with diesel fuel can just as well

be operated with palm biodiesel or a blend of palm biodiesel and

petroleum diesel. This applies both to the engine performance and

long-term operation. The results of the engine performance for the OM

352 engines can be translated to other direct-injection engines.’

Labels:

bio-diesel,

commodity,

investment,

machineries,

palm oil

Mar 9, 2013

BioDiesel Solutions: FAQs 6 to 12

6. Is palm biodiesel a sustainable energy?

Generally, sustainable energy is about using energy wisely, and using

energy produced by clean technologies or from renewable sources and

causes no long-term damage to the environment. Palm biodiesel produced

in Malaysia is from palm oil, which is produced in a sustainable manner

and their use conserve our crude petroleum reserve and contributes to

our own economy. Malaysian palm biodiesel is therefore a sustainable

energy.

7. Palm oil: for food or for fuel?

The main proportion of palm oil will still be used for food. Malaysia

together with Indonesia has agreed to gazette a total of 6 million

tonnes of palm oil to be used as biofuel. Malaysia and Indonesia being

the two largest palm oil producers in the world produced a total of 36

million tonnes of palm oil in 2007. In 2011, the combined production of

Palm Oil for Malaysia and Indonesia was 42.81 million tons out of 50.32

million tons of the Global Production.

8. Can palm oil compete with other vegetable oils as feed-stock for biofuel and biodiesel?

One of the important criteria for any vegetable oils to be used as

biofuel is availability at competitive price. Palm oil meets this

criterion perfectly. It is already common knowledge within the world of

oils and fats that the development of the oil palm industry in Malaysia

has been remarkable. Malaysia takes pride of the fact that within a

relatively short period of time, we have become the world’s second

largest producer and exporter of palm oil products in the international

oils and fats market. Furthermore, the advantage which palm oil holds

over other oils and fats lies in its productivity, yield and efficiency

factors. Oil palm is the most productive oil bearing plant species

known. The yield of palm oil per unit area is 5 to 10 times higher than

rapeseed and soybean oil, respectively. Considering the comparative

yields of various oil bearing crops, oil palm is clearly the most

efficiently produced oil in the world today. When the world is looking

at vegetable oils as renewable fuel, palm oil will undoubtedly stand out

among other vegetable oils. This yield factor alone is adequate for the

world to decide which vegetable oil should be produced to meet the

expanding requirement for Greener and Cleaner Energy’ for its growing

population.

9. What is the latest development of MPOB biodiesel production technology?

The technology has been licensed to two companies who will build and

sell biodiesel plants based on MPOB technology. In 2008, these licensees

have sold a total of 10 plants within and outside Malaysia.

10. What are the other potential applications of palm

biodiesel in addition to being used as diesel substitute for

transportation?

Palm biodiesel has many other applications besides being used as

diesel substitute for transportation. It can be used as heating fuel in

domestic and commercial boilers. Biodiesel exhibits better solvency

power and thus is a better solvent than petroleum-based solvent. Palm

biodiesel can also be used as feedstock for oleochemical industry such

as α-sulphonated methyl esters for the production of liquid detergent.

11. Is Palm biodiesel economically viable?

Generally, it is not economically viable to use palm biodiesel in

Malaysia as our petroleum diesel is relatively cheap. This is mainly due

to the subsidy for petroleum diesel for transport given by our Malaysia

Government. It is very feasible for overseas markets where the

petroleum diesel is very expensive and price for biodiesel is high. This

makes palm biodiesel very competitive as palm oil is cheaper than other

vegetable oils.

12. Do you have palm biodiesel with low pour point to be used in temperate countries?

Palm biodiesel with low pour point (winter grade) that is suitable as

diesel substitute in temperate countries has been successfully produced

by MPOB. The normal palm biodiesel with pour point of + 15°C can only

be used in tropical countries while the winter grade palm biodiesel

(-21°C to 0°C) can be used in temperate countries to meet the seasonal

pour point requirements (summer grade, 0°C; spring and autumn grades,

-10°C; and winter grade, -20°C).

Labels:

bio-diesel,

commodity,

FAQs,

investment,

palm oil

Mar 8, 2013

BioDiesel Solutions: FAQs 1 to 5

1. What is palm biodiesel?

Palm biodiesel is an alternative fuel derived from palm oil and can

be used in compression ignition engines, i.e. diesel engines without any

modifications. It refers to methyl esters derived from palm oil through

a process known as ‘transesterification’.

2. What is the difference between biofuels and biodiesel?

Biofuels are alternative fuels derived from renewable natural

resources, e.g. vegetable oils and their derivatives, bioethanol,

biomass, etc. Biodiesel refers to alkyl esters of long chain fatty acids

derived from vegetable oils and their derivatives, animal fats, waste

oils, etc. Therefore, biodiesel is one type of biofuel.

3. Who was behind the initial research and development (R&D) of biodiesel from palm oil?

Malaysian Palm Oil Board (MPOB) started the R&D of biodiesel from

palm oil and its products way back in 1982. Since then, MPOB has

conducted extensive R&D in using palm biodiesel as diesel

substitute.

4. What is ENVO DIESEL?

ENVO DIESEL is MPOB’s brand name for the blend of processed palm oil and petroleum diesel.

5. What is processed palm oil?

Processed palm oil is the oil that can be used for blending with

petroleum diesel. It can be refined, bleached and deodorized (RBD) palm

oil or palm olein, as well as methyl esters of RBD palm oil or palm

olein.

Labels:

bio-diesel,

commodity,

FAQs,

investment,

palm oil

Mar 7, 2013

BioDiesel Solutions; Introduction

The depletion of fossil fuels, coupled with the increasing awareness of environmental protection, has led to concerted and escalating R&D efforts in search of renewable and environmental-friendly alternative energy sources. The recent strong demand for renewable fuels has resulted in tremendous increased production of biofuels worldwide. As major producer of palm oil, Malaysia through MPOB has carried out extensive R&D on the production of biodiesel from palm oil and its products since the 1980s. MPOB has now become one of the successful technology providers for the production of biodiesel with the building of its first commercial plant in 2006. The homegrown palm biodiesel production technology is comparable if not better than overseas technologies. This is due to the in-depth understanding of the indigenous properties and characteristics of palm oil. The biodiesel produced meets the stringent quality requirements of the international biodiesel specifications, namely ASTM D6751 and EN 14214.

According to the World Commission on the Environment and Development,

sustainable development is defined as development that ‘meets the needs

of the present without compromising the ability of future generations

to meet their own needs’. Sustainable palm oil production comprises

legal, economically viable, environmentally appropriate and socially

beneficial management and operations. Thus, the use of sustainable palm

oil for the production of palm biodiesel will make the Malaysian palm

biodiesel industry sustainable. This concept focuses primarily on the

proper practices required to achieve sustainability.

From the economic point of view, the utilization of the bioenergy

such as biodiesel may not be as economically attractive as using

conventional energy, but this should not prevent its widespread use as

the concern towards depletion of the fossil fuels and increasing

environmental concerns must also be addressed.

Labels:

bio-diesel,

commodity,

investment,

palm oil

Mar 6, 2013

Mar 5, 2013

Palm Oil Biofuel to Curb Oversupply

by Linda Yulisman, The Jakarta Post | Headlines | Thu, January 10 2013, 11:45 AM

Indonesia, the world’s biggest palm oil producer, is mulling a move to produce biofuel to manage abundant local supplies.

Deputy Trade Minister Bayu Krisnamurthi said on Wednesday that the move would become a “fundamental solution” to curb an oversupply of the commodity in the overseas market that, has in part, contributed to falling international prices.

“We are trying to convince various stakeholders that if we can convert up to 3 million tons of palm oil into biodiesel, it will be a game changer in the market,” he said.

The government has allocated a subsidy of Rp 3,000 (31 US cents) per liter for biodiesel, with a total allocation of 900,000 kiloliters. It is hoped that the subsidy will promote the use of renewable energy sources and cut dependence on fossil fuels.

The endorsement of biofuel, either biodiesel or bioethanol, started in 2008 following increases in the price of fuel. The government issued a ministerial decree that required the blend of all oil-based fuels with biofuels.

However, domestic biofuel consumption never reached the designated annual targets. In 2010 consumption only stood at 223,041 kiloliters, far lower than the target of 1.73 million.

The domestic industry, on the other hand, has seen robust overseas demand for biofuel with exports last year topping 1.4 million tons, particularly to the European Union (EU), where the member countries are bracing to apply a new renewable energy directive. Bayu said that the local absorption of palm oil for bio diesel would also create healthy competition with its top rival, Malaysia, the second biggest palm oil producer.

Indonesia introduced a new tax policy in late 2011 that cut export tax on refined palm oil products from 25 percent to 10 percent to encourage local producers to export value-added products.

The new structure complements a progressive tax on the export of crude palm oil (CPO) that begins when the commodity’s price is more than $750 per ton. Exporters are required to pay an export tax of 1.5 percent for every $50 increase in the price from the ceiling.

After its local palm oil industry had been affected by Indonesia’s policy, Malaysia responded in October last year by cutting the export tax to between 4.5 percent and 8.5 percent from 23 percent, a move that cut down stocks by encouraging exports.

“The gap between the export tax of Indonesia and Malaysia will range between 2.5 percent and 3 percent, which will be around $25 per ton. It will make a difference, but will not lift up prices because the problem lies in supply,” Bayu explained.

Bayu added that the government expected the local palm oil industry to enlarge the capacity of its storage tanks from around 2.5 million tons, which can only hold a one-month stock supply, to 8 million tons to save three-month stocks.

Deputy Trade Minister Bayu Krisnamurthi said on Wednesday that the move would become a “fundamental solution” to curb an oversupply of the commodity in the overseas market that, has in part, contributed to falling international prices.

“We are trying to convince various stakeholders that if we can convert up to 3 million tons of palm oil into biodiesel, it will be a game changer in the market,” he said.

The government has allocated a subsidy of Rp 3,000 (31 US cents) per liter for biodiesel, with a total allocation of 900,000 kiloliters. It is hoped that the subsidy will promote the use of renewable energy sources and cut dependence on fossil fuels.

The endorsement of biofuel, either biodiesel or bioethanol, started in 2008 following increases in the price of fuel. The government issued a ministerial decree that required the blend of all oil-based fuels with biofuels.

However, domestic biofuel consumption never reached the designated annual targets. In 2010 consumption only stood at 223,041 kiloliters, far lower than the target of 1.73 million.

The domestic industry, on the other hand, has seen robust overseas demand for biofuel with exports last year topping 1.4 million tons, particularly to the European Union (EU), where the member countries are bracing to apply a new renewable energy directive. Bayu said that the local absorption of palm oil for bio diesel would also create healthy competition with its top rival, Malaysia, the second biggest palm oil producer.

Indonesia introduced a new tax policy in late 2011 that cut export tax on refined palm oil products from 25 percent to 10 percent to encourage local producers to export value-added products.

The new structure complements a progressive tax on the export of crude palm oil (CPO) that begins when the commodity’s price is more than $750 per ton. Exporters are required to pay an export tax of 1.5 percent for every $50 increase in the price from the ceiling.

After its local palm oil industry had been affected by Indonesia’s policy, Malaysia responded in October last year by cutting the export tax to between 4.5 percent and 8.5 percent from 23 percent, a move that cut down stocks by encouraging exports.

“The gap between the export tax of Indonesia and Malaysia will range between 2.5 percent and 3 percent, which will be around $25 per ton. It will make a difference, but will not lift up prices because the problem lies in supply,” Bayu explained.

Bayu added that the government expected the local palm oil industry to enlarge the capacity of its storage tanks from around 2.5 million tons, which can only hold a one-month stock supply, to 8 million tons to save three-month stocks.

Labels:

bio-diesel,

commodity,

investment,

palm product

Mar 3, 2013

Is Biodiesel Made From Palm Oil Threatening ..?

Many environmental organisations and conservationists have been

warning us that eating foods and using biodiesel made from palm oil is

having a direct effect upon and threatening the survival of that much

loved primate the Orangutan.

So what's all the fuss about?

Environmentalists

have generally been largely supportive of the adoption of biodiesel

because, apart from being biodegradable, it gives off fewer emissions

when used in our vehicles. Not all biodiesel fuel is the same however,

some are better than others in the way they are produced and

environmental organisations have begun to question oil palm cultivation

especially, in recent years, how large areas of natural rainforest have

been cleared to make way for oil palm plantations. It is argued that

apart from the loss of forest ecosystems, oil palm cultivation has

become a major polluter on a local level due to indiscriminate use of

petroleum based pesticides and fertilizers. This has lead to soils

becoming so polluted over time that many previously fertile areas have

become wastelands.

What has given rise to this deforestation?

Western

governments have largely embraced the need to cut emissions and have

set aggressive targets encompassing the use of so called first

generation Biofuels made from food crops. The transportation sector has

been singled out due to the fact it is a major volume source of carbon

emissions. It could be argued that this has contributed directly to the

rapid development of the Biofuels industry and marketplace. Also the

rise in the cost of crude oil to record levels by mid 2008 meant palm

oil has become an increasingly important agricultural crop in tropical

countries with Malaysia and Indonesia seeing the opportunity for

increased exploitation. These two countries account now for around 85%

of palm oil production across the world. This area of the world is also

the natural habitat of Orangutans and the increased deforestation is now

a threat to their very existence.

But why is Palm Oil so important?

Quite

simply oil palm is the most productive oil seed there is and it can

produce over 10 times more crude oil per hectare than soybeans and over

20 times more than corn. Another factor making palm oil in increasing

demand is apart from being used in Biodiesel production, it is also used

as an ingredient in many other day to day household foodstuffs as well

as cosmetics. Ironically, oil palm may be more ecologically friendly due

its higher yield factor in theory requiring less land by a significant

factor than traditional crops. Many environmental organisations, oil

companies and western governments recognise this and are beginning to

try to put the case to the local governments concerned.

But oil prices are going down now so will demand for palm oil drop?

Palm

oil prices tend to move in step with the price of crude oil and during

the second half of 2008 prices have fallen rapidly also as a result of

the global recession demand for palm oil should slow down. Critically,

does this mean we will see a slow down in the expansion of oil palm

plantations? Supply and demand economics for palm oil suggest it should

do, but the sceptics amongst us have maintained that oil palm

development may in fact be a cover for something that is far more

profitable - logging. In Indonesia millions of hectares of forest have

been cleared for plantation development and plans are in place to double

oil palm production over the next 15 to 20 years spilling over into

Borneo. Logging is a much more profitable to both the logging companies

and the local governments.

What of the Orangutans?

I'm not sure Orangutans understand the economics and politics in their region of the world. If they did then it is likely they would be putting pressure on the governments both locally and around the world to re-consider the plans they have for what is still the largest tropical rainforest in Asia. Perhaps the local agricultural ministers in question should look at the mounting pressure from the West, look to their conscience and re-evaluate all available information. Perhaps they would then realise that the long term survival of the regions biodiversity is not only crucial for local indigenous peoples but also our friendly Orangutans and who knows perhaps the very survival of our planet in the long term.

Article Source: http://EzineArticles.com/1723743

Labels:

article,

bio-diesel,

estate,

oil palm tree,

plantation,

RSPO,

WWF

Feb 28, 2013

Feb 27, 2013

Feb 26, 2013

Feb 25, 2013

BioDiesel from Palm Oil

100% CRUDE PALM

OIL REFINED (RBD) PALM OIL PALM OLEIN & PALM STEARIN are EXCELLENT

VEGETABLE OILs THAT CAN BE USED TO PRODUCE YOUR BIODIESEL!

Palm Oil

Biodiesel is produced by a reaction of a palm oil or animal fat with an

alcohol such as methanol or ethanol in the presence of a catalyst to

yield mono-alkyl esters and glycerin, which is removed.

Palm Oil

Biodiesel is produced by a reaction of a palm oil or animal fat with an

alcohol such as methanol or ethanol in the presence of a catalyst to

yield mono-alkyl esters and glycerin, which is removed. With the increase in awareness and importance attached to environmental issues such as global warming, more environment-friendly fuels are being developed as alternatives to fossil fuel. One such fuel, which has been gaining prominence in recent years, is biodiesel. Clean and renewable, biofuel has been touted as the answer to the issue of the diminishing of energy reserves.

The advantages of palm oil biodiesel, drawn from the field trials are no modification of the engines is required, good engine performance, cleaner exhaust emission and comparable fuel consumption in comparison with the petroleum diesel.

6 REASONS WHY PALM OIL IS BETTER FOR BIODIESEL:

(i) Abundantly available and stable supply.

(ii) Crude Palm Oil can be broken down into many more useful fractions.

(iii) Cheaper than all oils especially Soybean Oil Did I mention, CHEAPER!

(iv) Already being used domestically

(v) Reduces our dependency on petroleum diesel

(vi) Biodegradable Eliminates harmful emissions

What is Palm Oil biodiesel?

Palm Oil Biodiesel is the name of a clean burning alternative fuel, produced from Palm Oil. Palm Oil Biodiesel contains no petroleum, but it can be blended at any level with petroleum diesel to create a biodiesel blend. It can be used in compression-ignition (diesel) engines with little or no modifications. Palm Oil Biodiesel is simple to use, biodegradable, nontoxic, and essentially free of sulfur and aromatics.

How is Palm Oil Biodiesel made?

Palm Oil Biodiesel is made through a chemical process called transesterification whereby the glycerin is separated from the Palm oil. The process leaves behind two products -- methyl esters (the chemical name for palm oil biodiesel) and glycerin (a valuable byproduct usually sold to be used in soaps and other products).

Is Palm Oil Biodiesel the same thing as raw vegetable palm oil?

No! Fuel-grade palm oil biodiesel must be produced to strict industry specifications (ASTM D6751) in order to insure proper performance. Palm Oil Biodiesel is one of the few biodiesels to have fully completed the health effects testing requirements of the 1990 Clean Air Act Amendments. Biodiesel that meets ASTM D6751 and is legally registered with the Environmental Protection Agency is a legal motor fuel for sale and distribution. Raw Palm Oil cannot meet biodiesel fuel specifications, it is not registered with the EPA, and it is not a legal motor fuel.

For entities seeking to adopt a definition of biodiesel for purposes such as federal or state statute, state or national divisions of weights and measures, or for any other purpose, the official definition consistent with other federal and state laws and Original Equipment Manufacturer (OEM) guidelines is as follows:

(i) Abundantly available and stable supply.

(ii) Crude Palm Oil can be broken down into many more useful fractions.

(iii) Cheaper than all oils especially Soybean Oil Did I mention, CHEAPER!

(iv) Already being used domestically

(v) Reduces our dependency on petroleum diesel

(vi) Biodegradable Eliminates harmful emissions

What is Palm Oil biodiesel?

Palm Oil Biodiesel is the name of a clean burning alternative fuel, produced from Palm Oil. Palm Oil Biodiesel contains no petroleum, but it can be blended at any level with petroleum diesel to create a biodiesel blend. It can be used in compression-ignition (diesel) engines with little or no modifications. Palm Oil Biodiesel is simple to use, biodegradable, nontoxic, and essentially free of sulfur and aromatics.

How is Palm Oil Biodiesel made?

Palm Oil Biodiesel is made through a chemical process called transesterification whereby the glycerin is separated from the Palm oil. The process leaves behind two products -- methyl esters (the chemical name for palm oil biodiesel) and glycerin (a valuable byproduct usually sold to be used in soaps and other products).

Is Palm Oil Biodiesel the same thing as raw vegetable palm oil?

No! Fuel-grade palm oil biodiesel must be produced to strict industry specifications (ASTM D6751) in order to insure proper performance. Palm Oil Biodiesel is one of the few biodiesels to have fully completed the health effects testing requirements of the 1990 Clean Air Act Amendments. Biodiesel that meets ASTM D6751 and is legally registered with the Environmental Protection Agency is a legal motor fuel for sale and distribution. Raw Palm Oil cannot meet biodiesel fuel specifications, it is not registered with the EPA, and it is not a legal motor fuel.

For entities seeking to adopt a definition of biodiesel for purposes such as federal or state statute, state or national divisions of weights and measures, or for any other purpose, the official definition consistent with other federal and state laws and Original Equipment Manufacturer (OEM) guidelines is as follows:

Palm Oil Biodiesel is defined as mono-alkyl esters of long chain fatty acids derived from Palm Oil vegetable oils which conform to ASTM D6751 specifications for use in diesel engines. Biodiesel refers to the pure fuel before blending with diesel fuel. Biodiesel blends are denoted as, "BXX" with "XX" representing the percentage of biodiesel contained in the blend (ie: B20 is 20% biodiesel, 80% petroleum diesel).

Why should I use palm oil biodiesel?

Palm Oil Biodiesel is better for the environment because it is made from renewable resources, i.e. Palm Oil and has lower emissions compared to petroleum diesel. It is less toxic than table salt and biodegrades as fast as sugar. Since it is made from renewable resources i.e. Palm Oil, its use decreases our dependence on foreign oil and contributes to our own economy.

Where do I get Palm oil biodiesel?

It can be purchased directly from biodiesel producers and marketers, petroleum distributors.

What is biodiesel?

Very

often, a broad, general description is used to define biodiesel in a

way that is easy to understand by the general public. However, when

these broad descriptions are adopted by an authoritative body as a

formal definition, they can include a wide range of experimental fuels

that are not biodiesel. The term "biodiesel" has a specific, technical

definition that has been agreed to through a painstaking process by

members of industry and government which has received full approval by

the American Society of Testing and Materials (ASTM), the premier

standard setting organization for fuels and fuel additives. That

definition is used for purposes such as alternative fuel designation,

EPA registration, or other regulatory purposes. Nonetheless, this

specific technical definition can be confusing to the general public.

General Definition of Biodiesel:

Biodiesel is a domestic, renewable fuel for diesel engines derived from natural oils like soybean oil, palm oil and which meets the specifications of ASTM D 6751.

Clarifying language to general definition:

Biodiesel can be used in any concentration with petroleum based diesel fuel in existing diesel engines with little or no modification. Biodiesel is not the same thing as raw vegetable oil. It is produced by a chemical process which removes the glycerin from the oil.

Technical Definition for Biodiesel (ASTM D 6751) and Biodiesel Blend:

Biodiesel, n-a fuel comprised of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats, designated B100, and meeting the requirements of ASTM D 6751.

Biodiesel Blend, n-a blend of biodiesel fuel meeting ASTM D 6751 with petroleum-based diesel fuel, designated BXX, where XX represents the volume percentage of biodiesel fuel in the blend.

Clarifying language to technical definition:

Biodiesel, as defined in D 6751, is registered with the US EPA as a fuel and a fuel additive under Section 211(b) of the Clean Air Act.

General Definition of Biodiesel:

Biodiesel is a domestic, renewable fuel for diesel engines derived from natural oils like soybean oil, palm oil and which meets the specifications of ASTM D 6751.

Clarifying language to general definition:

Biodiesel can be used in any concentration with petroleum based diesel fuel in existing diesel engines with little or no modification. Biodiesel is not the same thing as raw vegetable oil. It is produced by a chemical process which removes the glycerin from the oil.

Technical Definition for Biodiesel (ASTM D 6751) and Biodiesel Blend:

Biodiesel, n-a fuel comprised of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats, designated B100, and meeting the requirements of ASTM D 6751.

Biodiesel Blend, n-a blend of biodiesel fuel meeting ASTM D 6751 with petroleum-based diesel fuel, designated BXX, where XX represents the volume percentage of biodiesel fuel in the blend.

Clarifying language to technical definition:

Biodiesel, as defined in D 6751, is registered with the US EPA as a fuel and a fuel additive under Section 211(b) of the Clean Air Act.

Labels:

bio-diesel,

CDM

Feb 15, 2013

10 Top Reasons to Make Biodiesel

1. Biodiesel is EASY to make. You can make Biodiesel in your kitchen!. Anybody can make biodiesel.

2. Biodiesel is BETTER than the Petro-diesel fuel. Biodiesel is cleaner. It cuts down on targeted emission - better for the environment and better for health.

3. Biodiesel provides good engine performance. Your diesel motor will run better and last longer on your home-made fuel.

4. The production and use of biodiesel create less carbon dioxide emission compared to petroleum diesel. Hence Causing less damage to the atmosphere.

5. The Raw Material for making Biodiesel is Renewable and Biodegradable.

You can make biodiesel from Vegetable Oil such as palm Oil.

6. Petroleum Oil Prices is increasing. Now, Biodiesel is at it's infancy. It is the best time for you to start experimenting with biodiesel and if you know how to make it, then when biodiesel is in demand, you will be at the top.

7. Biodiesel can be used neat or blended with petroleum diesel in any proportions.

So, when petroleum diesel is too highly priced, like it is now, your biodiesel will be very much in demand.

8. No modification is required on your diesel engine. Biodiesel operates in conventional combustion-ignition engines, from light to heavy-duty just like petroleum diesel and no engine modifications are required.

9. Fossil fuel is depleting. Fossil fuel products have been used by mankind as a source of energy and it was assumed that they will last forever. Time has changed: with fossil fuel on depletion and global warming on the increase, it is time to create a sustainable world.

2. Biodiesel is BETTER than the Petro-diesel fuel. Biodiesel is cleaner. It cuts down on targeted emission - better for the environment and better for health.

3. Biodiesel provides good engine performance. Your diesel motor will run better and last longer on your home-made fuel.

4. The production and use of biodiesel create less carbon dioxide emission compared to petroleum diesel. Hence Causing less damage to the atmosphere.

5. The Raw Material for making Biodiesel is Renewable and Biodegradable.

You can make biodiesel from Vegetable Oil such as palm Oil.

6. Petroleum Oil Prices is increasing. Now, Biodiesel is at it's infancy. It is the best time for you to start experimenting with biodiesel and if you know how to make it, then when biodiesel is in demand, you will be at the top.

7. Biodiesel can be used neat or blended with petroleum diesel in any proportions.

So, when petroleum diesel is too highly priced, like it is now, your biodiesel will be very much in demand.

8. No modification is required on your diesel engine. Biodiesel operates in conventional combustion-ignition engines, from light to heavy-duty just like petroleum diesel and no engine modifications are required.

9. Fossil fuel is depleting. Fossil fuel products have been used by mankind as a source of energy and it was assumed that they will last forever. Time has changed: with fossil fuel on depletion and global warming on the increase, it is time to create a sustainable world.

10. Best of all is the GREAT feeling of freedom, independence and empowerment it will give you.

Labels:

article,

bio-diesel,

investment

Subscribe to:

Posts (Atom)